History

-

1939--1948

1937,With the outbreak of the Anti-Japanese War in full swing, the Japanese army invaded China to meet the needs of the war, adopting the tactic of “war for war” and plundering China's resources on a large scale. To this end, the Japanese North China Salt Industry Co., Ltd. planned to build a factory in the Tanggu Daliangzi area for extracting bromine from the bitter brine of the salt fields, and for by-producing potassium chloride, magnesium chloride and other munitions products.

1939.12.28,Japan's “Kitakyushu Development Co., Ltd.” approved the construction plan for the 25,000-ton per year brine plant, which became the official date for the establishment of Dagu Chemical. The groundbreaking of the plant was in 1942, and the plant was put into operation in 1943. By the time of the victory in the war, the plant had a total of electrolysis, bromine, magnesium chloride, bleaching powder and other production facilities.

1945,After the victory of the war, the Kuomintang took over the then Dagu Chemical Plant, during which the enterprise changed hands several times and went through trials and tribulations, with inconsistency in management, lack of professional staff, and lack of equipment and devices, the production was in a state of chaos and relative stagnation.

-

1949--1959

1948.12.23,The 136th Division of the 46th Army of the Northeast Field Army of the Chinese People's Liberation Army liberated the Daliangzi area, and Dagu Chemical was liberated. The new China was waiting for the new, and the company was revitalized under the light of the new society.

1951,The trademark of “Red Triple Crystal” was officially launched and continues to this day, and has now been recognized as a “Famous Trademark of China” and a “Famous Trademark of Tianjin” brand.

1953-1957,Under the leadership of the Party, the enterprise has determined the development route of marine chemical industry, which is mainly to develop chlor-alkali series products, and the scale of production has been rapidly developing and expanding by tapping the potentials for renovation and innovation. The majority of the workers widely carry out the socialist labor competition for increasing production and saving, and the enthusiasm of drilling technology, learning management, and comparing energy is high, and a number of model workers emerge, which promotes the rapid development of production.

1958.11.14,When Vice President Zhu De inspected Tianjin, he received Plant Director Li Zhizhen and wrote an inscription for Dagu Chemical Plant (endeavor to develop the basic chemical industry to better meet the needs of the people).

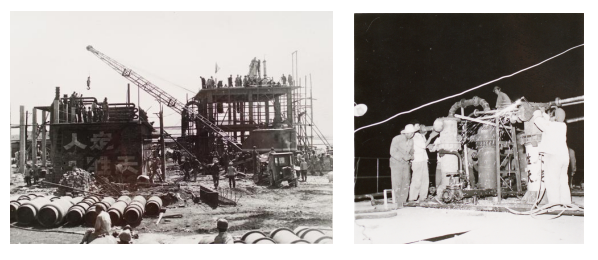

1959,Five projects, including polyvinyl chloride, caustic soda, glacial acetic acid, calcium carbide, and six-six-six complex, were put into production, which opened a new chapter in the development of marine chemical industry of Dagu Chemical from then on.

-

1960--1977

During the period of socialist construction, the majority of workers were enthusiastic and went all out to develop production. During more than ten years, Dagu Chemical made positive contributions to the national construction.

1960-1963,Enterprises to carry out “four”, “three no”, “four new”, “five anti-” and other learning technology, environmental protection, improve production, grasp the The company's production efficiency has been greatly improved by the activities of learning technology, protecting the environment, improving production and controlling work style. During the period, the company explored independently and adopted the pressure balance method to reform the shaft seal of PVC polymerization kettle, which was praised by the Ministry of Chemical Industry and popularized to the national PVC production enterprises.

1964-1974,Sixty-six, potassium chlorate fine crystal, sodium peroxide, boiler water treatment, polyvinyl chloride, etc. have adopted new production process one after another, and the output and quality have been greatly improved. 110 workshop, sodium metal, sodium peroxide, sodium peroxide, polycrystalline silicon, pentachlorophenol, chloroethanol, synthesized hydrochloric acid and other production equipment have been put into operation one after another, and the enterprise's product structure has gradually been enriched, which lays a solid foundation for the subsequent development.

1976.7.28,The Tangshan earthquake affected Tanggu and caused great damage to the enterprise, part of the plant collapsed, 70% of the equipment was damaged, and the production was stopped for a while. The whole factory went all out in the work of earthquake relief and resumption of production. It took only 18 days to start production one after another, and by the end of September, it was basically restored to the level before the earthquake, and became an advanced unit in Tianjin for self-reliance, earthquake relief and resumption of production.

-

1978--1999

After the Third Plenary Session of the Eleventh Central Committee of the CPC, facing the new situation of reform and opening up, Dagu Chemical has emancipated its mind, innovated, relied on scientific and technological progress, and carried out technological renovation of old enterprises. Adhering to the development idea of “combining the introduction of foreign capital and domestic financing, combining the introduction of foreign advanced technology with technological reform, combining the strengthening of management with the return on investment” and the policy of “internal management, external market, development and science and technology”, Dagu Chemical has consolidated its production base and further improved its technological level. The foundation of the enterprise has been consolidated and the technical level has been further improved.

1980,Lindane, an international general-purpose high-efficiency insecticide, was put into production, increasing production value and generating foreign exchange for the enterprise.

1985.8,The thermal power plant project was completed and put into operation, and the enterprise set up a thermal workshop. The installed capacity is 12,000 kilowatts and the steam supply capacity is 140 tons per hour.

1990,The second phase of ion membrane 20,000 tons/year caustic soda plant was put into operation.

1990-1996,Enterprises focus on the layout of the chemical industry, marine chemical products plate successfully built, has completed the second and third phase of the ionic membrane caustic soda plant expansion, caustic soda production for the first time exceeded the annual output of 120,000 tons mark. The annual output of 20,000 tons of propylene oxide project passed the completion and acceptance. PVC SG7 and SG8 resins were developed and tested, and put into production, and the whole system of PVC plant with an annual output of 40,000 tons was successfully tested. The introduction of oxychlorination VCM plant, PVC resin polymerization plant and other projects, so that the production route of PVC from the previous single calcium carbide method to calcium carbide method, ethylene method and other ways of production, realizing the expansion of the enterprise from the marine chemical industry to the petrochemical industry, and laying a solid foundation for the further development of the enterprise.

-

2000--2011

Entering the twenty-first century, Dagu Chemical takes the east wind of the development and opening up of Tianjin Binhai New Area, and releases its own ideal with unremitting will to develop in this land of hope in the Lingang Economic Zone, and achieves proud results, making new contributions to Tianjin and Bohua Group.

2003-2008,The company continues to expand the production capacity of its main products, with caustic soda production capacity reaching 320,000 tons/year, PVC production capacity reaching 800,000 tons/year, and propylene oxide production exceeding 10,000 tons per month for the first time. The downstream product of propylene oxide developed by the company has also completed the expansion and transformation, and the production capacity has reached 30,000 tons/year.

2004,Dagu Chemical implemented the shareholding system reform and established Tianjin Dagu Chemical Industry Co.

2007.5,The company's main business income for the first time to achieve more than 10 billion yuan, completed 10.501 billion yuan.

2010,Dagu Chemical Lingang plant styrene and ABS units were put into production one after another, and the Lingang plant project with an annual output of 500,000 tons of styrene and 400,000 tons of ABS resin was successfully docked with the city's one-million-ton ethylene project. The completion and production of Lingang plant marks that Dagu Chemical has become a world-leading styrene and ABS producer, and it extends the petrochemical product chain while filling the gaps of the products in Tianjin at that time, effectively improves the overall level of technological equipment and scientific and technological innovation ability of the enterprise, and accelerates the adjustment of the industrial structure and the diversification of the capital structure, and contributes to the creation of high-end, high-quality and high-tech product structure combining the marine chemical industry and the petrochemical industry, and further improves the economic quality of the enterprise. In the process of accelerating the diversified adjustment of industrial structure and capital structure, it is of great significance to create a high-end, high-quality and high-tech product structure combining marine chemicals and petrochemicals, and further enhance the quality and efficiency of economic development.

-

2012--Now

Entering the new era, Dagu Chemical, guided by Xi Jinping's thought of socialism with Chinese characteristics in the new era, took the initiative to cope with the great changes that have not occurred in a century, nurtured new opportunities by turning crises into new opportunities, opened up new opportunities by welcoming changes, further strengthened the reform and innovation, deepened the tapping of potentials and increased efficiency in a systematic way, and pushed forward the transformation and development in a high quality way, so as to realize the double leap in output value and efficiency, and achieved the historical achievements of “two chemical industries” relocation. “Historic achievement of relocation.

2015, Dagu Chemical started the “two chemical” relocation and transformation planning, “efficient operation of the old district, port quality and efficiency, the construction and development of the south port” as the main line, comprehensively launched the “two lines and three places” battle, the majority of party cadres and workers work hard, hard work and struggle. The majority of party cadres and workers hard work, hard work and struggle, it took 7 years to put the South Port into operation, to create Bohua Nangang new materials industry base.

2022,The company's Tanggu plant was shut down, and the main business was formally relocated to Lingang plant, after 83 years of Dagu Chemical ushered in the historical transformation of Lingang plant to shoulder the heavy responsibility of the future development of Dagu Chemical, and the brand-new Bohua Development was formally completed and put into operation, carrying the hope of the “red three crystals” to sail away.

2022,Liquid-solid circulating fluidized bed hydrogen peroxide direct oxidation of propylene to produce propylene oxide new process (FHPPO) through the China Petroleum and Chemical Industry Federation of the organization of the 72 hours of continuous operation of the on-site assessment, organized by the Petrochemical Federation of the evaluation of the experts unanimously agreed that the project's technology and process has reached the international leading level.